Description

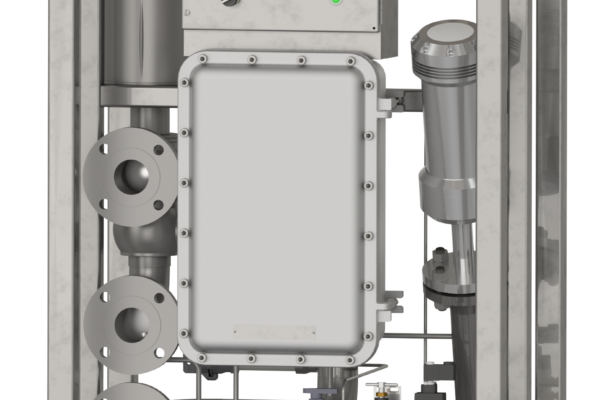

The measuring device is a high reliability, high precision, and compact side stream measuring system. The system uses a well-tested and robust measuring technique called laser induced fluorescence. Laser induced fluorescence means a laser is fired into the liquid stream, and the wavelength of the reflected light is measured and evaluated to accurately determine the current oil in water content. Traditional fluorescence- based analyzers measure on a single wavelength, but the measuring device of the unit can provide full spectral analysis, and such capability provides several necessary advantages:

- Eliminate chemical interference that occurs in 99% of applications.

- Oil type detection that offers the ability to switch calibration depending on water content, so when different oil types come onstream or different chemicals are introduced the analyzer will automatically select the correct calibration curve.

- Verifies that the analyzer is reading accurately when commissioned and continues to do so despite process changes

Easily implemented in existing systems, and has several interface options:

- Direct PPM read-out on probe display

- Probe internal fault alarm, potential free contact

- High PPM alarm, potential free contact

- 4-20mA active signal indicating the currently measured PPM value.

- Can be connected to by a standard CAT5/CAT6 cable to view the PPM read-out directly in a control room.

Suitable for most applications, yet requires little to operate:

- 100 barg design pressure, 0-10 barg standard operating pressure (higher options available)

- -20 to 60 degrees ambient temperature

- -20 to 200 degrees process temperature

- 24VDC, 6A power consumption

Approved for use in ATEX zone 1/ UL Class 1 Division 1 environments, and MEPC 107(49) certified.