Description

Víxla is derived from the Norse word transformation. A fitting description for our core purpose:

Transform Waste into a Valuable Resource.

We intentionally choose a name that set us apart from our competitors, because the distinction goes beyond the name. Our solution has six key features which distinguish us from other solutions on the market:

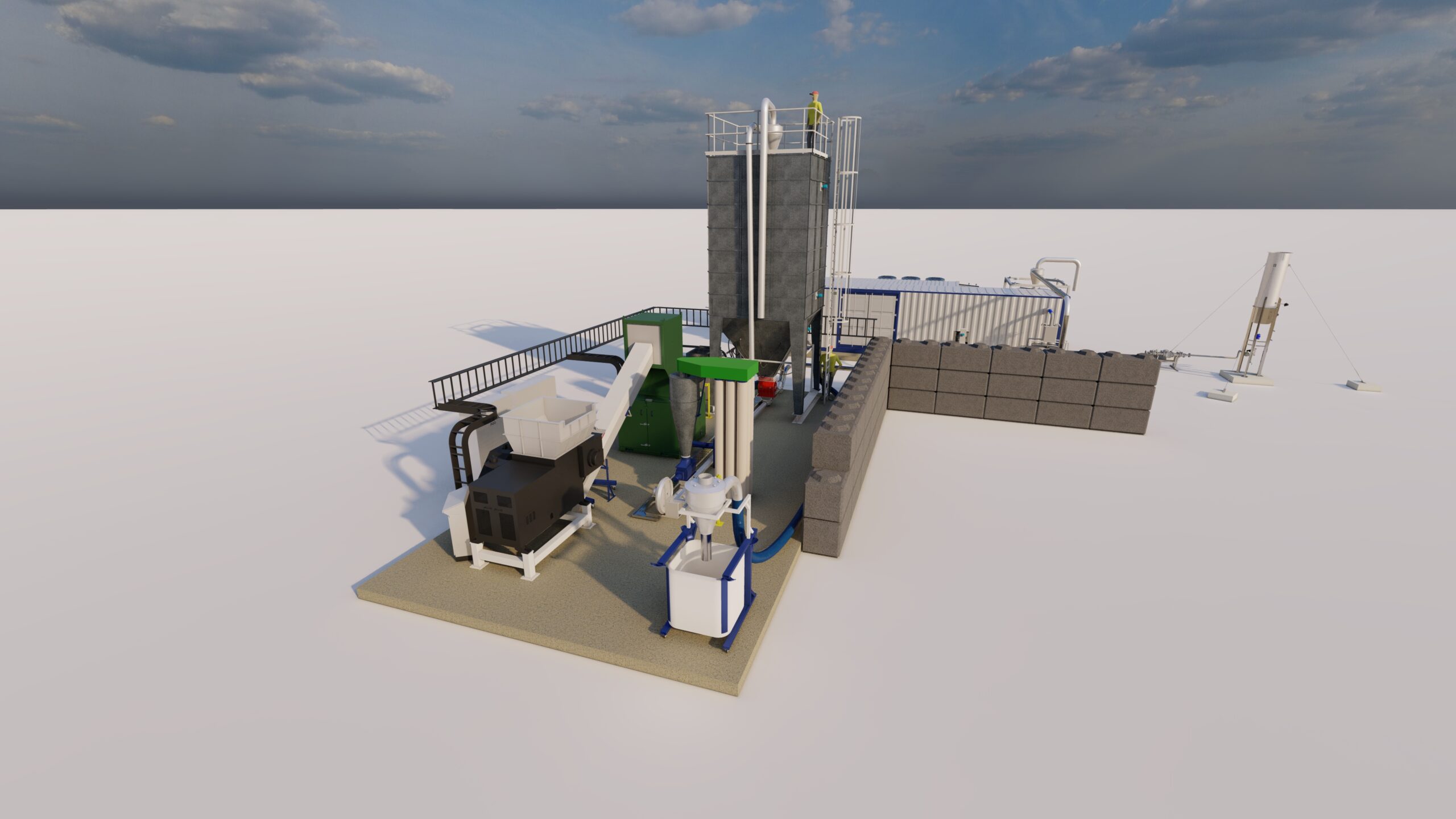

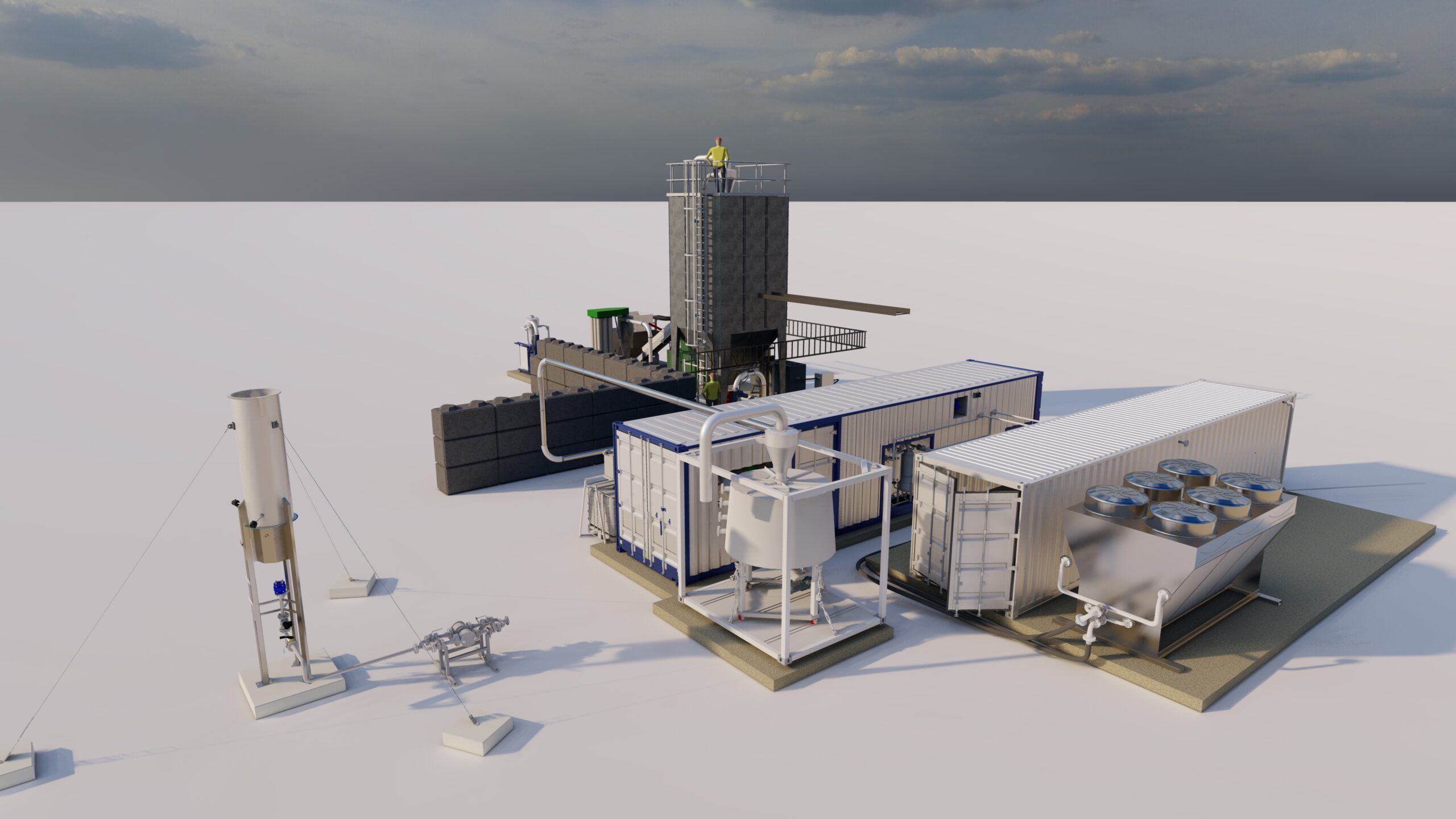

- A Decentralized Approach:

We bring the solution directly to the source of the problem – plastic waste. A decentralized approach results in substantial financial and environmental savings, distinguishing us from established concepts with centralized super sites.

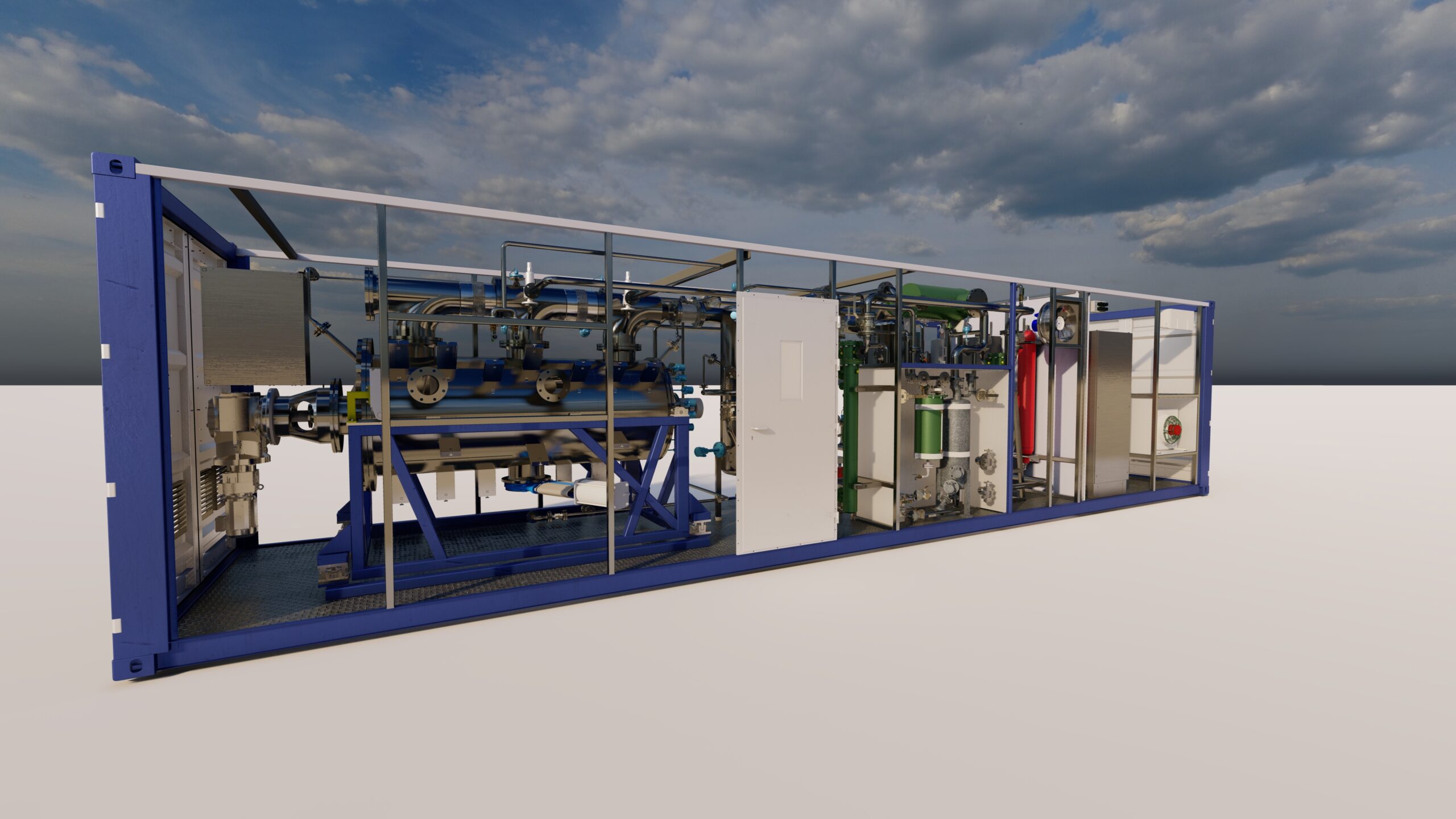

- Containerized and Mobile:

Our container-based solution facilitates mobility, allowing for targeted waste cleanup on-site. After completing the task, our customers can relocate the system, providing unparalleled flexibility.

- Modular and Scalable:

The Víxla system is designed to handle 5 tons per day but can be easily scaled for larger projects. The modular approach facilitates for multiple systems on the same site to achieve as high capacity as needed.

- Efficient and Clean:

With a conversion rate of 80-85%, our technology effectively transforms the majority of the waste into a renewable product. The residual byproduct predominantly comprises non-condensable gas, which serves to power the system, leading to a significant reduction in energy consumption and an impressively low carbon footprint. Additionally, a minimal percentage of carbon ash is produced, offering versatile applications or options for responsible disposal.

- Low Entry Barriers:

Our solution has significantly lower CAPEX compared to competitors, ensuring accessibility to a broader market. - One-Stop-Shop:

We have formed strategic partnerships with companies that offer our customers a comprehensive end-to-end solution for plastic waste recycling, spanning from pretreatment systems to the final stages of off-take and sales of the end product.

Invest in the Víxla system and take a step towards a cleaner, more sustainable future.

For further information, please contact:

Simen Moberg

Sales and Marketing Director

(+47) 478 52 004 | simen@eagle.no